Our Product

Column Cap Central’s post, column, and mailbox caps are unmatched in quality, are easy to install, and are built to last.

Durability

At Column Cap Central, our caps are designed with durability in mind. Commercial builders, architects and municipalities often specify our product due to its’ exceptional versatility and durability. Our products have a lightweight foam interior and a tough hybrid urethane exterior. This unique combination of plastic and foam makes our caps resistant to rot, termites, and moisture. Moreover, our caps are earth friendly, in comparison to traditional concrete. Additionally, they are able to withstand temperature cycling.

Ease Of Install

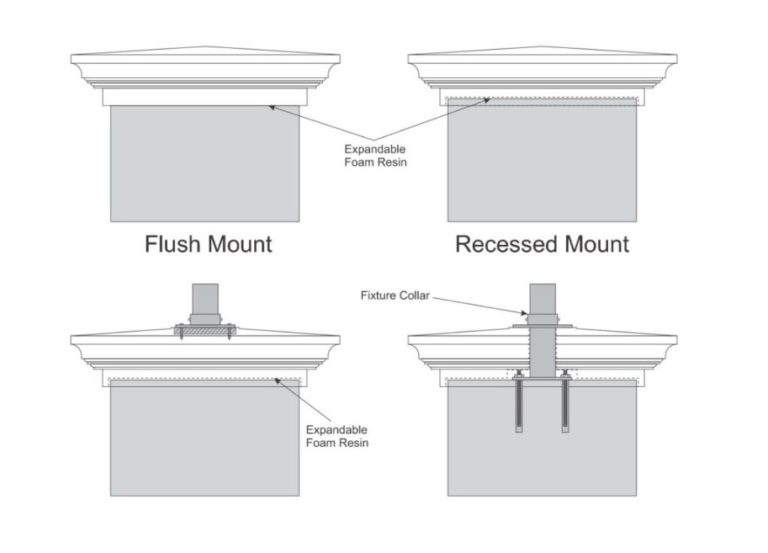

Column, Post, Pier and Mailbox caps can be installed in one of two ways: flush mount install or recessed install. Additionally, we can modify any of our standard designs or manufacture a custom cap design to include substrate and a center hole to accommodate a light on the top of your cap.

All Column Cap Central caps must be installed using non-petroleum based adhesives. Acceptable adhesives include PL Premium and Bostick A940. After the caps are adhered to the column, we recommend using any latex caulk of your choosing to seal around the edge where the cap meets the column, this will ensure that long term exposure to moisture doesn’t unseal the cap from the column.

Free Estimates

Column Cap Central is happy to offer free estimates by online quote or call.

Resources

Contact Us

Flush Mount Installation

A flush mount install is the most common cap installation method. In this method the caps are adhered atop the column. If you are installing your cap on a new column or an area that is finished smooth – flush mount installs work well. Spread your non-petroleum based adhesive atop the column and seal the edge with a latex caulk.

Recessed Mount Installation

Column caps can also be installed using the recessed mount installation method. The cap will be recessed 1″ deep (or however deep you specify) to slide over your column. This method allows the installer to hide common imperfections such as an uneven column or unattractive base. Non-petroleum based adhesive will be placed atop the column. Next, you will place your over column. Finally, you can use a latex calk around the bottom of the cap to seal the area where the cap meets the column.

Adhesives for Cap Installation

All Column Cap Central caps must be installed using non-petroleum based adhesives. Acceptable adhesives include PL Premium and Bostick A940. After the caps are adhered to the column, we recommend using any latex caulk of your choosing to seal around the edge where the cap meets the column, this will ensure that long term exposure to moisture doesn’t unseal the cap from the column.

Light Fixture Accommodation

All of our caps are able to be customized to include substrate and a center hole. While we do not offer the lights, we will place substrate at the top of the cap – so you can drill into the cap. The center hole will allow you to run your electrical wires through your cap into your column.

If you plan to install lights into your column, pier or mailbox cap let us know ahead of time so we can include substrate. Due to our unique proprietary manufacturing process, you cannot drill into our caps without substrate or you will void the quality guarantee.

Resources

Columns

At Column Cap Central, the choice of colors and textures is virtually limitless. Our artists possess the capability to sculpt, imitate and reproduce an endless choice of materials and textures, creating a cost effective solution with an artistic touch that is second to none.

Column Cap Central offers two finish options: our standard refinish texture and a heavier stucco finish. The standard refinish texture best simulates the appearance of concrete. It is sprayed on and up close looks similar to the texture of an orange peel. The heavier stucco finish is similar to the look of a popcorn stucco ceiling. All caps will be finished with our standard refinish stucco texture by default, unless the heavier texture is specified prior to placing your order.

Colors

Enhance the finished appearance of your column with a custom color. We offer thousands of column cap colors to choose from – at no additional charge. We can match any Sherwin Williams, Benjamin Moore, 1 Shot, PMS or Masterwall Color. If you prefer to match an existing concrete or building color, send us a color sample. You can also choose one of our standard colors.

Materials

Our line of featherweight building products are manufactured using an Expanded Polystyrene (EPS) core. EPS is an innovative building material that is moisture resistant, termite resistant, able to withstand temperature cycling and earth friendly. The EPS foam is then encapsulated in a proprietary hard coat which makes the cap resistant to rot, moisture, heat, freeze and thaw, offering exceptional durability within a lightweight cap. Finally, the caps are sprayed with a light stucco finish (one color of your choice) to simulate the appearance of concrete.

Our line of ‘foam core” building products offers many benefits including ease of installation, as our caps and piers are 95% lighter than traditional precast products, reducing the chance of job site injuries and worker’s compensation claims. In addition, our foam core product is highly versatile allowing for greater custom design capabilities, while saving you money.